How to Rebarrel a Firearm

This month our discussion will cover the steps, tools, machines, and measuring devices you will need to rebarrel and chamber a rifle. Hopefully, I can explain it in a way that is easily understood and as detailed as possible. For my discussion, I will be referencing the Remington 700 action. The Remington 700 is the most popular action to be rebarreled.

Machines and Tools

Before I jump into the process of chambering a rifle, I want to make sure you have the proper tools and machines. The most important machine is the metal turning lathe. The lathe will be used in the whole process of chambering and rebarreling a rifle. You will the proper cutting tooling for the lathe. As well as the chamber reamer for the caliber you plan on chambering the rifle with. You will also need an indicating rod for the caliber you plan on using.

Next, you will need measuring tools like a micrometer, calipers, depth gauge, thread pitch gauge, and most importantly “Go and No Go” gauges for the caliber you are chambering. Finally, you will need a good barrel vise.

Now that you have all the necessary machines and tools, let’s get started. I will be using some terminology you may or may not have heard of before. To make sure everyone is on the same page, I have added a diagram below.

Critical Measurement Points

In order to cut in a new chamber, you need to measure some critical points of the action. These measurements will determine how long the threaded tenon (#3 on diagram) needs to be and how deep you will need to cut the chamber (#6). The measurements you will take will determine the proper head space for your rifle. Achieving the proper headspace, is highly important. Proper head space will make your rifle more accurate, reloading easier, and most importantly, it will make the rifle safe. Too much head space can make the case swell, blow out primers, or even split shell casings. So when you are measuring these critical points, make sure you measure multiple times.

Insert your stripped-down bolt-action receiver in a bench vise vertically. Insert the bolt into the action. There are three points that you need to measure. All points are measured from the receiver face.

Now that you have all these measurements, you can put the barrel in the lathe. If you plan on doing a lot of chambering and rebarreling, I recommend purchasing “The Complete Illustrated Guide to Precision Rifle Barrel Fitting” by John Hinnant. There is a lot of good information on all action types. It also includes worksheets to determining headspace, list of tools and supplies for reference.

Preparing the Barrel

My method of cutting chambers may differ from other Smiths. However, I place the barrel in the chuck and only leave enough room to make cuts on the breech end. Some Smiths use a steady rest. Other Smiths use a “Spider” to get the barrel straight. You will need a 4 jaw chuck or better on your lathe to get the barrel indicated correctly. A three-jaw chuck does not have enough adjustment to center the barrel. If that is all you have, the spider I mentioned above will help you get the barrel aligned. I use the live center on the tail stock to get me close to center.

Then, I adjust the chuck jaws in to hold the barrel. Next, insert the Indicating rod in the rifling on the breech end of the barrel. Using an indicating gauge, make the bore of the rifle as square as possible to your cutting tools. This is called concentricity. The OD and the ID of your barrel may not be the same. Most barrel manufacturers get the ID and OD close.

But the ID is the most important alignment you need to make. Now start tightening and loosening the jaws on your head stock to get the barrel in the lathe perfectly square. After I get my indicating gauge to move +/- 0.0005 or less I am ready to start the chambering process.

Chambering

The first area you will cut down is the breech face. This area is usually stamped with the caliber of the rifling and a date code of when it was made. Cut the tenon diameter to the diameter needed. For Remington barrels that OD is 1.060. From the measurements you made earlier, you will know how long the tenon needs to be. At this point, you can cut the threads on the tenon so it will thread onto the action. Make sure you know what the threads per inch (TPI) are. The next area that needs to be cut is the counter bore area.

This is the area where the bolt nose fits inside the breech area. I use a counter bore cutter that is designed for the Remington 700. Install the floating reamer holder in the tail stock of your lathe. Insert your counter bore cutting tool in the holder. The measurement you made earlier gives you the depth required of the counter bore. Slowly advance the tool, measuring the depth of your cut with the depth gauge. The last thing to do is chamber. I have used chamber reamers from Pacific Tool and Manson. I’ve also rented reamers from 4D Rentals.

You will need a floating reamer holder to assist in chambering. It fits into the tail stock of your lathe. Cutting the chamber is probably the longest process in chambering. You can only make short cuts. Use a generous amount of cutting oil on the reamer. As you cut the reamer will fill up with metal chips. If you don’t keep it clean, the chips will scar the chamber as you cut. I usually cut thirty to fifty thousandths of an inch, then clean off the reamer.

Use compressed air to blow out the chips inside the chamber. Then clean off the chips that are on the reamer by dipping the reamer in a jar of mineral spirits.

Next blow off the reamer with air. Continue this process until you get to the point where you are close to finishing. This is where you start using your head space gauges. From the measurements you made in the beginning, it determines how far your gauge should protrude out of the chamber. The only way to make it as accurate as possible, is to screw the action on the barrel with the recoil lug installed.

Once the action is tight, insert the gauge in the chamber and close the bolt. In a perfect world, the bolt will close and your rifle will be perfectly head spaced. That has never happen for me.

I keep cutting with the reamer. But make smaller cuts in this process. You can tell when you are getting close to perfect head space. The bolt will get closer to closing. You will continue making shorter cuts till you get there. Once the bolt closes, you need to grab your No Go gauge and insert it in the chamber to make sure the bolt doesn’t close.

Once you get to that point, you have successfully chambered a rifle. Lastly put the barrel in the barrel vise, line up your recoil lug and tighten the action on the barrel. Recheck your head space after you have everything tight.

You Did It!

Semper Fi!

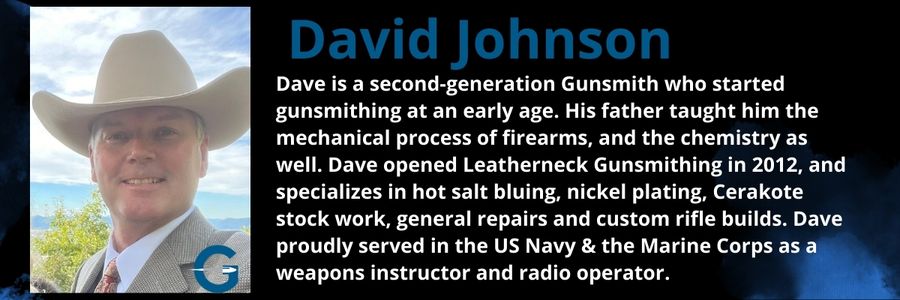

By: David Johnson, Leatherneck Gunsmithing