Gunsmithing Horror Stories

If you have been Gunsmithing for any length of time you will definitely have some stories to tell. Every once in a while, the story may be a bad one. Learning from those horror stories will make you a better, more seasoned Gunsmith. Hopefully you can look back and laugh at some of the mistakes made. I’ll share some of my own stories.

Over the years I’ve met many people, and some have turned into good friends. One of these friends started out as my UPS driver (still is). Sam is a great fella and an avid hunter. He had been having some issues with his favorite turkey gun, a camo Charles Daly 12 Guage pump. I started by looking over the firearm to see if there were any broken parts, and making sure no metal shavings were present. Everything looked good. I fired a couple rounds through it and sure enough the bolt release button wasn’t holding like it should.

It would almost depress itself and allow the bolt to disengage just enough to keep it from firing. Sam had missed a couple large gobblers and was ready to wrap the shotgun around a tree. As I was inspecting the shotgun, I noticed that it was pretty dirty. I thought that maybe some sand or dirt had made its way into the parts and was making it malfunction. So, I fired up the Dicro 909 soap tank and disassembled the Charles Daly. When I deep clean firearms, I use hot soapy water most of the time, Brownells Dicro 909 is the best stuff I have found.

Let the gun sit in the soapy water for 20 minutes or so and scrub everything with a gun cleaning brush. It will get a gun almost spotless. I dropped the shotgun in the tank and set my timer for 20 minutes. I came back to the tank after fifteen minutes to start scrubbing with the brush. When I looked in and I almost threw up in the tank. All the camo on the gun was floating on top the hot soapy water. I didn’t know that the camo on the shotgun was hydro dipped.

There I was, with my UPS driver’s favorite turkey gun ruined. I had no idea what I was going to do. I picked up the phone and made one of the most uncomfortable calls I have ever made. I had only been in business for a couple years, and this was my first mistake I couldn’t fix. I figured Sam would start losing my packages, put me last on his list, or just throw the packages out of his door as he drove by. Sam was great, He said he didn’t like the camo pattern anyway, so I cerakoted the whole piece for free and got the shotgun working like it should.

I have stepped into horror stories knowing that I shouldn’t take on the job. This was the case when I picked up a customers Winchester Model 1873 from one of my local gun shops. This piece had been in the customers family since it was new. The 1873 had seen better days.

This rifle was missing many parts, the stocks were black, and as you can see the finish on the rifle was terrible. Finding the parts was the most challenging. I tried all my usual suppliers like Jack First, Numrich, and Homestead Parts. Some parts were available, but I was still missing the bolt. Winchester made these rifles in many different calibers, and this rifle was in 32-40 caliber. I finally found the bolt, but it took months to find. Finally after months of searching for parts and a lot of time spent on the restoration of the rifle, I was finally finished.

My lesson learned on this job was to make sure you account for all your time. Your research, and part ordering time is billable time. I spent much more time finding parts than I made on this job.

As you can see, horror projects can either happen to you when your not expecting it, or they can be self-induced projects. Learning about each gun that comes in your shop will greatly reduce your chances of having those projects turn into horror stories you can tell. I will often read about the firearm before I do anything to it. I research to see if anyone else has had the same problems with the firearm and what they did to fix the issue. You can learn from other people’s mistakes. It will save you time, money, and a lot of headaches.

If you are doing a complete restoration on a firearm, make sure that the restoration is something you can complete. Knowing your limits or knowing your capabilities will keep you from having the horror stories to tell in the future. Ultimately you want the firearm to be safe to use and you to be proud of your work. Having your customer thoroughly satisfied with the work you did on it has to be one of the most rewarding feelings you can have.

Semper Fi!

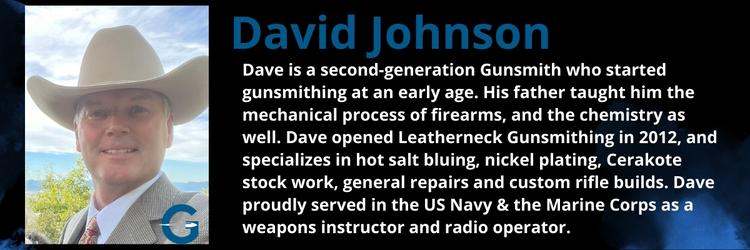

Written by: David Johnson, Leatherneck Gunsmithing