Build Projects are Important to your Gunsmithing Career

In today’s discussion we will talk about an AR15 Build. The beauty of the AR15 and why so many like it, is because it is highly customizable. You can use the same lower assembly for more than 20 calibers. Pop two pins, add a different upper assembly, a new magazine, and you are shooting a completely different caliber.

Please note that my views on the AR15 are based on my experience, articles read, customer feedback, and personal preference. I am in no way saying one manufacturer or product is better than any other. Now that the disclaimer is out of the way, let’s get started!

The main components of the AR are as follows: the stripped lower (frame), the stripped upper, the barrel, the bolt carrier group (BCG), the gas system, the internal fire control system, the additional hardware, and the stocks. The key to building a custom AR15 is knowing how your customer will use the rifle. An AR being used for short range target plinking, for instance, will use different components than someone who wants to shoot out to 500 yards.

Lowers and Uppers

This will likely cause quite a stir, or ruffle some feathers, but a lower is a lower. What I mean by this is that all lowers are made to a mil/spec. Cast or billet, they all must meet a specification. From the material it’s made of, to every dimension, hole, hole depth, thread pattern, every component has to be consistent. For builds that I have done for myself and customers, I usually purchase an inexpensive lower and upper. In all the AR builds I have done, and all the people I have spoken with, not one lower or upper has failed, cracked, or been out of specification. As you take on build projects, you will learn the importance of following the stablished military standards.

Fire Controls and other components

I am a proponent of spending less on pins, springs, bolt catches, upper receiver hardware, selectors, and magazine releases. Instead, I look to spend the money on a good trigger.—you and your customer will appreciate it. A standard, out-of-the box AR stock trigger has a 5.5 to 9.5-pound pull. Depending on what you are using the AR for, that trigger weight could mean the difference between a hit or a miss.

A lightweight trigger is best for competition shooting or hunting, while a heavier trigger is best for home defense and to prevent accidental discharges. The less time holding the scope or sights on a target, the more accurate of a shot. Remember, as a gunsmith, you want to identify your customer’s needs, as each customization has a deliberate purpose.

Aftermarket triggers come as a complete drop-in assembly. Other aftermarket triggers look like a stock trigger, but are polished in a way to reduce the pull travel and different springs are used to achieve the pull weight needed. A couple items to note: If you are installing a drop-in trigger, you need to purchase an anti-walk trigger and hammer pins. Standard pins will slowly walk their way out of their holes and make the weapon inoperable.

Secondly, if you are building for competition (3-gun application), a larger bolt release, and magazine release will save the shooter valuable time, because they are easier to find on the weapon. Changes to components can be made rather quickly if you decide to change something in the future.

Barrels

The barrel is one of the most important parts of your rifle. This area must be researched to meet the needs of your customer. Pay special attention to caliber, length of barrel, barrel profile, and barrel weight, as they help guide your research. For home defense, for instance, you can use a standard 16” barrel with a regular twist rate. Your consumer may want to use a shorter barrel to maneuver through dark and congested areas, for instance—which will then lead to more research on the rules of short barrel rifles.

Longer barrels with shorter twist rates are better for long range shooting. Long-range shooting has many things to consider as well. Items like bullet weight, bullet length, powder used, brass used and many other variables are crucial to your research. Do your homework on all these items and come up with the best possible barrel. AR barrels are made by 8-10 manufacturers in the country. Keeping that in mind, the $300 barrel could be made by the same manufacturer as the $150 barrel you are looking at. I’m not saying go with the cheapest, just that some investigation can go a long way.

Bolt Carrier Group (BCG)

The other most important component of your AR build is the bolt. Just like the rest of the AR, there are many different options to choose from. Coatings on types of BCG’s range from Parkerized (Phosphate) and Black Nitride to Nickel Boron to Titanium Nitride (TiN). Reliability is what you want in a bolt carrier group, or BCG. Some finishes are slicker and easier to clean, and some finishes are more durable over time.

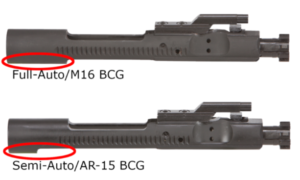

The coating on a MIL/Spec BCG is Parkerized Phosphate. Hundreds of thousands of M16’s, M4’s, and its variants have gone to combat and have functioned as they should. It is a little harder to keep clean and may appear ugly to shooters. One final note on BCG’s: you will see M16 or Full Auto BCG’s advertised. The diagram below shows the difference:

It is not illegal to install a full-auto BCG in an AR15. The bolt alone does not make the weapon fully automatic. Full auto BCG’s are also easier to find because more of them are made, so more are available.

Gas System

This topic will be brief. There are two types of operating systems on the AR. Direct Impingement (DI) and Gas Piston. Direct Impingement is the most used. DI guns push on the action directly, using a tube to direct gas back to the bolt, forcing in backwards to cycle the firearm. Firearms with gas pistons don’t use that method. Instead, they force gas against a metal piston, which in turn pushes back against the bolt to cycle the gun.

Gas piston guns run significantly cleaner than DI guns do. They keep gas and carbon fouling from entering the “shooting parts” of the gun. If you or your customer shoots a lot of full-auto or thousands of rounds a year, the Gas Piston system may be a good option to explore.

Stocks & Accessories (Furniture)

From stocks to handguards, sights, lights, and optics there are thousands of options in the marketplace to choose from for your AR. You can purchase them from your local gun shop or even on Amazon. As stated above a couple of times, do your research, watch videos, ask others who have AR’s what has worked for them. Listen to your customer to provide the best options to meet their needs.

The Tools

Finally, having the proper tools to do the build project is very important. Receiver blocks and an AR multitool are at the top of the list of most important tools. You will also need a lightweight hammer and a roll pin punch set. Like AR furniture, there are many manufacturers of AR specific tools. Manufacturers and distributors like Wheeler, Real-Avid, Brownells, and Midway USA make or carry good quality tools. Read the reviews.

Your MGS Build

Building and customizing an AR will be a great learning experience. It requires you to read and research the products, options and the pros and cons. This knowledge will carry over into future AR builds and will also help in other builds that are not done on the AR platform.

The Modern Gun School Advanced Gunsmithing II Program is designed to combine your course knowledge with the inner workings of a firearm. While you have the option of the F1 Firearms’ AR15, you also have an option in LoneWolf’s Polymer G17 Pistol and Traditions’ Muzzleloader. With hands-on projects meshed with the convenience of online education, our build projects can help you make the leap into your new career!

~Semper Fi

By: David Johnson, Leatherneck Gunsmithing