Building a Workbench On-The-Go

A proper workbench is solid enough to support a vise. Sometimes, however, work calls to field locations, like ranges. With no guarantee of finding a suitable surface, a portable workbench may be required. What goes into such a thing?

The Essentials

By definition, a portable bench must be man-portable, or at least its components should be. Since even small workbenches can weigh 80 pounds or more, it’s best to find something that may be disassembled easily. Braced designs work best to resist torque imposed by a vise attached to one of the edges.

Besides a vise and AR15/AR10 receiver blocks, an adjustable rifle holder for more traditional guns would be quite helpful. While the best workbench is both large and solid, something must be sacrificed for portability. It should be size rather than build: a wide flimsy bench is useless, while a more modestly sized solid one may be used, just less efficiently.

Top-Tier Tools

Tools should be easily transported as well: a roller cart with drawers should suffice for labeled cases holding gauges, rulers, punches, and other small tools. Labeled and marked with color tape or stickers, they will be easy to find when needed. The same labeling would ensure that all tools would be returned to the cart at the end of the workday, with none left on location.

Magnetic dishes for screws and other small parts are equally important, as is a light-tone drop-cloth to keep dropped objects from disappearing in grass or gravel. Speaking of screws: bags of the most common screws, clearly labeled, should be carried, along with various grades of thread locker. For reverse tasks, bring penetrating oil and lubricants.

Necessary Accessories

Lighting and protection from the elements come next. A bright LED panel with dual (AC and battery) power source would provide necessary illumination for close-up work. A pop-up tent with add-on side panels, ideally translucent for a well-lit workspace during the day even at remote ranges, would allow effective work without depending purely on battery-operated lights.

Considering the likelihood of test firing repaired or adjusted guns, a set of cleaning rods is essential to have on hands for clearing stuck cases or bullets. Rods for verifying centering of muzzle threads are also needed, along with bore lights and green laser bore sights.

Making Do

The limitation of field-portable gunsmithing is in the power tools: there’s no carrying a drill press or a lathe to remote ranges. However, the vast majority of problems experienced at the range can be fixed without them. Custom build and upgrades requiring heavier machinery can wait, while troubleshooting broken or mis-adjusted guns is best done on the spot. It’s amazing how many “100% reliable” competition guns aren’t at just the least opportune moments. Portable gunsmithing bench to the rescue!

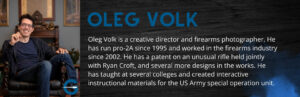

Written by: Oleg Volk, Firearms Photographer