Scope Mounting: 3 Spring Hunting Steps

Spring Hunting Season can catch people off-guard. Before your first hunt, you can take the necessary steps to best prepare for success. This could include creating an inventory, cleaning and prepping your weapons, practicing your marksmanship, even the final schedule of hunting dates. One discipline that many hunters forget is scope mounting, and its importance for Spring hunting. Though this process is straightforward, it does require some special tools. Let’s go over this process.

Step One: Select the right base & scope rings.

In order to install a scope you need two components. Scope bases and scope rings. Scope bases are sold for the specific firearm you are working on. Scope rings are sold by scope tube size and height. For bases two common styles are Picatinny and Weaver. They are the most popular and what I usually prefer. A solid rail will span the length of the action where you are installing the base. The holes are predrilled for the firearm already. So, the holes in the base and the firearm should line up. These mounts usually come with mounting screws to attach the base to the firearm. But I would recommend you to purchase a couple of scope mounting screw sets . I use both torx and standard blade screw sets.

Step Two: Install and tighten the base.

For the purposes of this discussion we are going to assume that the holes in the firearm have already been pre-drilled to mount a scope. Most of the firearms today come that way. First, you need to make sure the threads are clean and tapped straight. I use a long screw with the same threads as the holes are tapped and run the screw in and back out. Next, lay your scope base on the receiver to make sure you have the right mount. Once you have determined everything is correct, install the screws by hand. Don’t tighten all the way down the first time. After you have tightened them down inspect the action or frame of the firearm to make sure the screws do not go too far into the action to interfere with the firearms operation.

I have had guns brought to me because the owner couldn’t open the bolt on his bolt action rifle, only to find out the screws he used to mount his scope base were too long. The long screws pinched his bolt in place. So, inspect the firearm functionality after you have installed the base. If you need shorter screws, the kits I mentioned come in handy. You can also grind down the screws, so they fit better. A simple metal file can be used to shorten the screw. It will thread right into the tapped hole. Now that everything is the right length, firearm operation is good, back the screws out and apply medium strength thread locker.

There are many different brands of thread lock on the market, I prefer Loctite. Add one small drop on each screw and install the scope base with the screws. If there are four holes on the base, alternate from the front screws to the rears screws when tightening. Most screw/base kits will tell you how many inch pounds to use when tightening the screws. Leupold bases say to use 20 inch/pounds. I use a Wheeler Fat Wrench to install bases and rings. It is very easy to set the torque-inch pounds required. I still alternate between the screws to make sure the base is installed flat on the firearm.

Step Three: Attach the appropriate scope rings.

Finding the right rings for the scope is probably the most difficult part of installing a scope. Scope rings come in in many heights, and some work needs to be done to find out what height you need. Some scope’s objective lenses are larger than others. Other scopes main tube can be one inch and up to 34mm in diameter. These different diameters will dictate what height rings you need. There are some articles on the web that will show you how to measure to determine the scope height you will need. When installing the rings on the base, I always try to get the rings in the center portion of the scope. That will give you the most adjustability for eye relief. You want the scope to move horizontally to adjust eye relief.

A picatinny rail is a rail with multiple slots therefore it is easier to center your scope rings. However, a Weaver-one piece mounts and other two-piece mounts have set areas where the rings can be installed. Don’t let that stress you out if you can’t find a picatinny rail for the rifle you are working on. Two-piece bases are designed to achieve the average eye relief for most scopes.

Position the bottom half of the scope rings on the scope bases and hand tighten the screw or screws. Up to this point you haven’t needed any special vise or cradle to hold the rifle level. Now, you will need a way to level the scope in the scope rings. I have used a SEGWAY Reticle leveler, it is by far the least expensive way to level your scope. I have used standard bubble levels and placed one on the top of the elevation cap and another level on another flat surface on the rifle. This method is tricky because it is hard to find flat surfaces on some rifles. I have recently started using the Real Avid Level Right Pro. It can be used on AR platform rifles as well as hunting rifles. It seems to do the job well. Now that the firearm is sitting level in its cradle or vice you can lay the scope down into the rings. Make sure your elevation turret is on top and your windage adjustment turret is on the right side of the firearm.

I have fixed many scope issues for customers who have installed the scope with the windage turret on top and the elevation turret to the left. This incorrect configuration makes it a difficult to be on target. Next, take the top ring and place it on the bottom ring portion. Place one drop of medium strength thread lock on each screw an insert them. Don’t tighten them all the way up. Check for reticle level as well as eye relief. Once everything is level, start tightening the screws. Alternate sides when tightening. You want equal pressure on both sides of the scope.

While tightening, continue to check your reticle and firearm levels, adjust if necessary. Just like the scope bases, scope ring screws also have a torque specification. Don’t over tighten past that specification or you can break the screws. It can be very difficult trying to pull broken screws out of a scope ring. Wipe off any excess thread lock and you have installed a scope. I usually bore sight the firearm using a Red Head bore sight kit as a courtesy to my customers. It’s a simple thing to do. And it gets them on paper when they start to fine tune the scope.

Samper Fi!

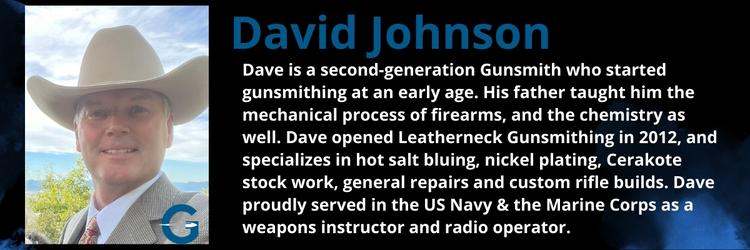

Written by: David Johnson, Leatherneck Gunsmithing